frequently asked questions /// FAQ Royal Exclusiv USA

Let’s start with the most frequently asked question: My pump doesn’t start.

Answer/solution:

Might foreign bodies have entered the pump head?

Might the impeller (or the bearing in the motor block) have been fitted incorrectly?

Is the bearing attached solidly to the shaft and has it hardened?

Is the bearing bush worn out?

Does the motor block or pump head have grinding marks?

Has the pump run dry?

Is electric power available for pump?

There is always a reason for a Red Dragon® pump not starting. In most cases, there will be scaling, a blockage or contamination. The electronics of the Red Dragon® pump stops when the power consumption (current drawn) is too high. If these causes can be eliminated and as long as there are no visual defects, please send the pump to the Royal Exclusiv® customer service. We explicitly point out that is prohibited to circumvent the electronics in the pump by constantly plugging in/unplugging the power plug to make the pump run again. If the Red Dragon® pump switches off, there is a problem which must be remedied. Alternatively, the fuse in the pump could get triggered = complete damage to the motor.

///////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////

1. Setting the skimmer (protein skimmer)

2. Water chemistry, strongly contaminated water and water flow

3. Noises and/or noise reduction

1. Correct piping

2. Cleaning and assembly

3. Noises and/or noise reduction

1. Wrongly piped pumps

2. Badly fouled and contaminated pumps

3. Decoupler set usage

__________________________________________________________________________________________________

My skimmer overflows when it foams, or does not foam at all.

Setting the skimmer:

With a new skimmer, it is completely normal for it to boil over (over flow). Especially at the beginning, the nozzle can be shut completely till it has settled down. Then, after about 2-3 days, the reference position can be taken (for RD3, there is no regulable nozzle, so that in this case, the pump should run at maximum setting for about 2-3 days and then its speed should be drawn down, so that the desired skimmer performance is reached.)

The wedge tube can be used in addition to the setting of the water level/water separator (water level in the skimmer) to clean when the pot is to be flooded, also. The Bubble King® DeLuxe, in contrast to the other Bubble King® families, has a telescopic tube. Here, the water level in the skimmer should be set only with the telescopic tube. Thus, the full cross-section of the outflow pipe always remains open and this is of particular advantage with varying water levels in the filter.

Please check the height of the water level/water separator, with the amount indicated in the operating instructions of your skimmer. Is this dividing line is too high, the absorbate is very liquid, is the dividing line too low is the absorbate dry or is not reaching the pot.

Water chemistry, excessively contaminated water and water flow:

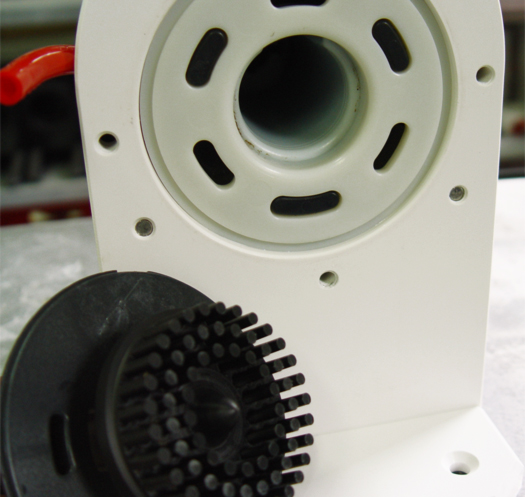

Ib) Dirt and scaling: Could the pin wheel be damaged? This happens very rarely, if, for example, a snail or a coral has got stuck in the pin wheel and is suspended between the pin wheel and the pump housing, in which case the pins get ground off and the output drops dramatically. Please check this visually; you can also send the pump to Royal Exclusiv® for checking. We offer various Service (pump output measurement, pump descaling and pump repairs)

The question of “why does my skimmer not skim” is actually a very complex theme that can also hardly ever be answered satisfactorily. All we can do is carry out the following actions: ...if the pump is running, and the tube is full of air bubbles, then the device is fine from a technical standpoint. There are actually only a few reasons why a Bubble King® does not foam :

a) The skimmer needs urgent cleaning, especially the nozzle and/or the pin wheel

b) And/or chemical reasons, which means that something is preventing or hampering the foam formation. There are many different variants here. An insignificant filter flow can also be responsible, or too little seafood/dirt or a wrongly placed skimmer (this cannot happen with a Dreambox).

c) Do you use a phosphate absorber?

Increased nitrate and phosphate values are always an indication of insufficient skimming (or of the necessity for a water change). Often, the output of a skimmer can be improved by increasing the flow to the filter. This could be the case, but need not necessarily be so.

Other reasons:

Ia) The air exhaust: Is the tube not perfectly filled with a white fluid, does it look almost as if one could look through it? In this case, it may be that too little air is being suctioned. This is quite easy to test - just pull off the RSAB-tube(air-hose) to the sound muffler(resonator) and check if things improve. If yes, this means that the sound muffler is blocked (salt crystals, foam material wet?) Please also check that the air suction pipe is completely clear. If any tinkering has been done on the air suction tube, this often has serious effects on a Bubble King. The cause could also be the nozzle, which can be pulled out without removing the skimmer or the pump from the filter. Here, the red 10 mm nipple in particular must be checked for scaling.

Ic) Surface tension: If the surface tension is reduced sharply, it may happen that no stable bubbles are formed and the contact pipe is hardly filled. This phenomenon occurs in our works in the test trough, when, for example, we chlorinate our salt water test beds. No skimming at all takes place during this time for 1-2 days. Or many hands have reached into the trough, which can result in a malfunction of the skimmer. Surface tension is reduced by all kinds of means. (The real killers are phosphate absorbers, silicate absorbers, activated carbon, vodka, epoxy glues, fresh filter mesh, but even various salt mixtures can have this effect.) Sea water aquariums have become real chemical kits. The ‘less is more’ principle applies here as well.

Id) Finally, the pump must be cleaned at regular intervals

The manual for your pump can be found here.

- Noises and/or noise reduction of your skimmer pump

Did you fit the nozzle correctly?

Did foreign bodies enter the pump head?

Was the impeller (or the bearing in the motor block) fitted incorrectly?

Is the bearing worn?

Does the motor block or pump head have grinding marks?

Please also check the air supply: is either the air hose, the noise muffler or the nozzle blocked?(gurgling noises)

Worth knowing:

A plastic trough absorbs the noise that is created much better than a glass trough. Do not use Styrofoam as insulation/anti-drumming mat; a neoprene material or an anti-humming mat would be much more suitable. It should be placed below the aquarium and filter trough.

Uncouple the skimming and delivery pumps with a silicon tube. So also, the filter box/motorering trough must be uncoupled from your piping. rubber supports (feets) below pumps and skimmers are a part of the basic equipment.

Brushless DC pumps, in contrast to asynchronous motors, do not have any known 50 Hz hum and thus distinguish themselves by their extremely silent running.

///////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////

Delivery pumps

My delivery pump does not run, or gets switched off after 3-5 start attempts?

- Correct piping:

On the intake side, a Red Dragon® pump must not be reduced. Whether used internally or externally, they ensure a smooth water supply. Dry running is fatal for any pump. Also, the piping on the intake side must be done only with bends and not with angles. On the pressure side, sizes can be enlarged or reduced by 1-2 DIN sizes, or a ball valve may be used, without any problems. None of our pumps is self-priming.

- Cleaning and maintenance:

A Red Dragon® pump must be cleaned and de-scaled regularly. On the one side, to ensure smooth working and on the other hand, to extend the service life. The manuals for the respective pump can be found here.

- Noises and/or noise reduction

If noise that was not generated earlier starts suddenly, this indicates a fault in the mechanics of the pump.

a) Maybe something penetrated into the pump.

b) Maybe the pump has to be cleaned and descaled.

c) There could be a technical fault.

d) The pump is running dry or has run dry.

e) Is the impeller abrading at the pump head? Are there grinding marks visible?

Nonetheless, the pump must be de-coupled from its piping.

You can find the de-coupling sets here.

Pump does not run?

Skimming and delivery pumps:

There is always a reason for a Red Dragon® pump not starting. In most cases, there will be scaling, a blockage or contamination. If the power consumption is excessively high, the electronics of the Red Dragon pump switches off.

If these causes can be eliminated and as long as there are no visual defects, please send the pump to the Royal Exclusiv® customer service.

///////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////

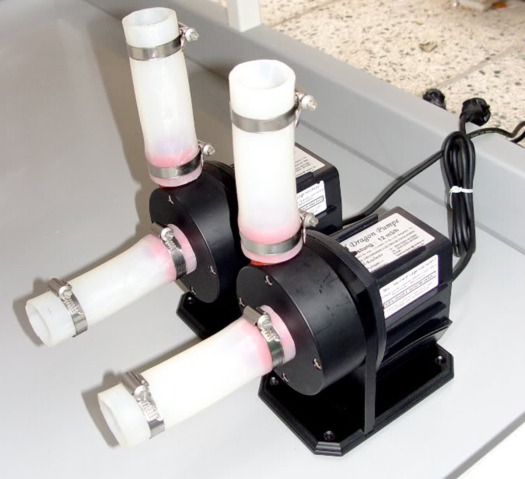

Not this way, please! Incorrect piping:

Clearly wrongly piped pumps, with angles right at the intake fitting. All our pumps are not self-priming.

///////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////

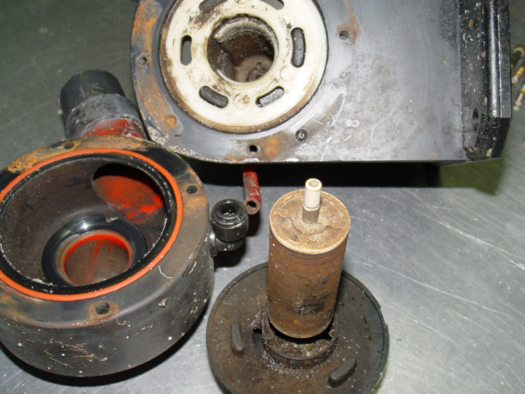

Not like this, please! Scaled and dirty pumps.

Badly scaled pumps and impellers. This pump came to a standstill because of the scaling.

///////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////

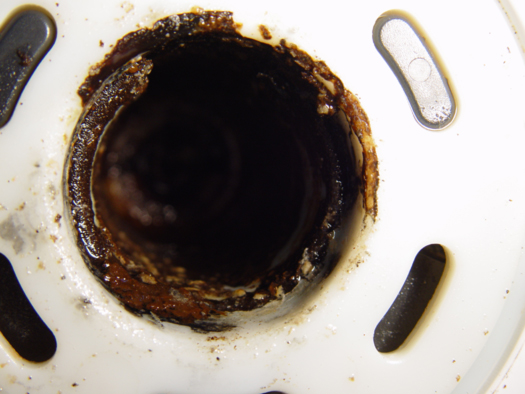

Not this way, please! Scaled and dirty pumps.

Very badly fouled pump - not a problem from the outside; if the pump looks like this on the outside, it cannot look much better inside. Regular maintenance and cleaning of your pump extends its service life!

///////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////

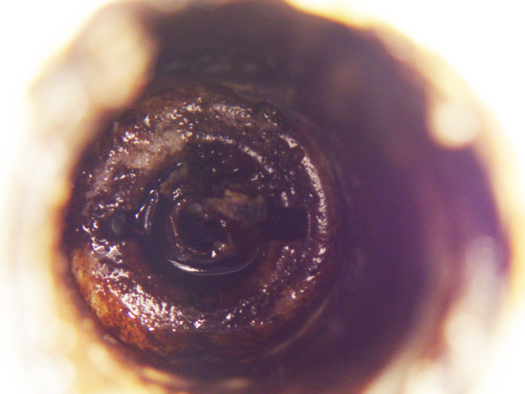

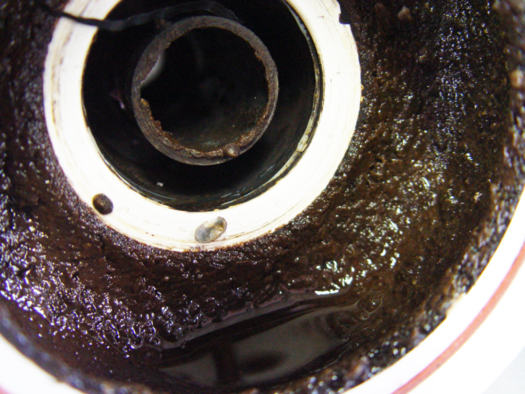

After expert cleaning, even this pump started without any problems.

Auch diese Pumpe lief nach einer fachgerechten Reinigung problemlos wieder an. Bitte für eine aussreichende Vorfilterung Ihres Wassers im Technikbecken/Filtersumpf sorgen.

This is what the pump looked like after expert cleaning.

///////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////

Please de-couple the pumps to avoid transfer of the vibrations to or from the piping system.

Pumps de-coupled on the intake and pressure sides with silicon hose and V4A (acid-resistant and hardened) hose clips.